Products

Get in touch about our Products

For over 30 years, we’ve been sourcing and testing the best equipment to suit our client needs. Which means we’ve built a trusted network of suppliers for various pieces of equipment.

We sell a range of quality products, including:

ELECTRIC HOISTS

MANUAL HOISTS

TROLLEYS

SKATES

Electric hoists

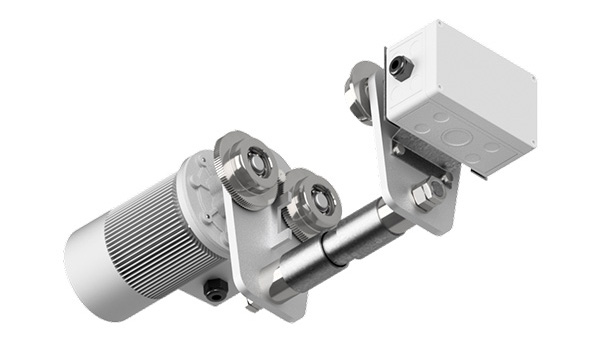

Electric hoists are lifting devices that use an electric motor to power the lifting and lowering of heavy loads. They are commonly used in industrial and manufacturing settings, as well as in construction and maintenance applications.

Electric hoists typically consist of a motorised drum or chain that is used to lift the load, as well as a series of gears and brakes that control the speed and movement of the load. They may be mounted on a variety of structures, such as overhead cranes, jib cranes, or gantry cranes, and may be configured in different ways depending on the application and load requirements.

Electric hoists are available in a range of sizes and capacities, from small hoists designed for light-duty lifting to larger hoists capable of lifting several tons. They may also be equipped with a variety of features, such as remote controls, overload protection, and variable speed controls, to enhance their performance and safety.

One of the key advantages of electric hoists is that they require less physical effort to operate than manual hoists, making them easier and more efficient to use. They also offer greater precision and control over the movement of the load, allowing for more precise positioning and placement.

Manual hoists

Manual hoists are lifting devices that use human power to lift and move heavy loads. They are commonly used in a wide range of applications, from construction and manufacturing to material handling and warehousing.

Manual hoists typically consist of a chain or wire rope that is wound around a drum or pulley, as well as a series of gears and brakes that control the movement of the load. They may be configured in different ways depending on the application and load requirements, and may be designed for lifting either vertically or horizontally.

There are several types of manual hoists available, including lever hoists, hand chain hoists, and manual wire rope hoists. Lever hoists use a lever to lift and lower the load, while hand chain hoists use a chain to perform the lifting operation. Manual wire rope hoists use a wire rope instead of a chain or cable, and are designed for heavy-duty lifting applications.

One of the key advantages of manual hoists is that they are simple and easy to operate, requiring minimal training and maintenance. They are also highly portable and can be used in a variety of settings, making them ideal for both indoor and outdoor applications.

However, manual hoists do require physical effort to operate, which can make them less efficient and more tiring to use than electric hoists. They may also be limited in terms of the loads they can lift and the speed at which they can lift them.

Trolleys

Trolleys, in the context of lifting and rigging, are devices used to support and move loads along a beam or track. They are commonly used in conjunction with overhead cranes or other lifting devices, and are designed to provide a means of moving heavy loads horizontally with ease.

Trolleys may be manual or powered, depending on the application and load requirements. Manual trolleys typically use hand cranks or chain hoists to move the load, while powered trolleys use electric motors or hydraulic systems to provide the necessary movement.

There are several types of trolleys available, including beam clamps, geared trolleys, and plain trolleys. Beam clamps are designed to attach directly to a beam or girder, while geared trolleys use gears to provide precise movement and positioning of the load. Plain trolleys, on the other hand, are designed to move freely along a track or beam and are typically used for lighter loads.

Trolleys are available in a range of sizes and capacities, and may be configured in different ways depending on the application and load requirements. They may be designed to fit specific beam or track sizes, and may be equipped with a variety of features, such as anti-derailment systems and overload protection, to enhance their performance and safety.

Skates

Skates, in the context of lifting and rigging, are devices used to support and move heavy loads along a flat surface. They are designed to be low-profile and highly manoeuvrable, and are commonly used in a variety of industrial and commercial settings.

Skates typically consist of a flat platform or base, often made of steel or other durable materials, as well as a series of wheels or rollers that enable the skate to move smoothly along the ground. They may be designed for use with different types of loads, including machinery, equipment, and other heavy objects.

There are several types of skates available, including straight-line skates, steerable skates, and adjustable skates. Straight-line skates are designed to move loads in a straight line, while steerable skates allow for greater control and manoeuvrability. Adjustable skates can be configured in different ways to accommodate different load sizes and shapes.

Skates are typically used in conjunction with other lifting and rigging equipment, such as cranes, hoists, and slings. They may be equipped with features such as locking mechanisms and brake systems to enhance their safety and stability during use.

Contact Us

Address

Anchor House, Riverside Industrial Estate, Market Harborough, Leicestershire LE16 7PT, United Kingdom

Phone

01858 465599

Opening hours

Mon to Fri / 8am-5pm