Loose tackle

Get in touch about our Loose Tackle

Loose tackle refers to the equipment and tools used for lifting and moving heavy objects in various industries, such as construction and manufacturing.

It includes a range of equipment such as eye bolts, eye nuts, lashings, slings, chains, ropes, hooks, and shackles.

Loose tackle is designed to make lifting and moving heavy objects safer and more efficient for workers.

It is important that the lifting tackle is properly inspected and maintained to ensure it is safe for use.

Loose tackle can vary in size and capacity, depending on the weight and dimensions of the objects being lifted.

Shackles

Shackles are a type of rigging hardware used in lifting and rigging applications to secure and connect chains, wire ropes, and other rigging components. They are designed to provide a strong and reliable connection between two or more pieces of equipment, and can be used in a wide range of industries, including construction, mining, and transportation.

Shackles are typically made from high-strength materials such as alloy steel, stainless steel, or carbon steel, and are available in a variety of shapes and sizes. The most common types of shackles are anchor shackles, which have a u-shaped design, and chain shackles, which have a more rounded shape.

Shackles are designed to be easy to use and maintain, and can be quickly and easily attached or detached from rigging components as needed. They typically feature a threaded pin or bolt that secures the shackle to the rigging component, and can be tightened or loosened using a wrench or other tool.

Shackles are an important component of many lifting and rigging systems, and must be selected and used carefully to ensure their safety and reliability. It is important to choose the right type of shackle for the specific application, and to carefully inspect and maintain shackles to ensure that they are free from defects or damage.

Eye bolts

Eye bolts are a type of fastener used in lifting and rigging applications to secure and connect wire ropes, chains, and other rigging components. They are designed to provide a strong and reliable connection point that can be easily attached or detached from the rigging components as needed.

Eye bolts typically feature a threaded shank with a circular loop or “eye” at one end. The eye is used to attach the eye bolt to the rigging component, while the threaded shank is used to secure the eye bolt to the object being lifted or rigged.

Eye bolts are typically made from high-strength materials such as alloy steel, stainless steel, or carbon steel, and are available in a variety of shapes and sizes. They may be designed with a shoulder or collar to provide additional strength and stability, or with a swivel mechanism to allow the rigging component to rotate freely.

Like other rigging hardware, eye bolts must be selected and used carefully to ensure their safety and reliability. It is important to choose the right type of eye bolt for the specific application, and to carefully inspect and maintain eye bolts to ensure that they are free from defects or damage.

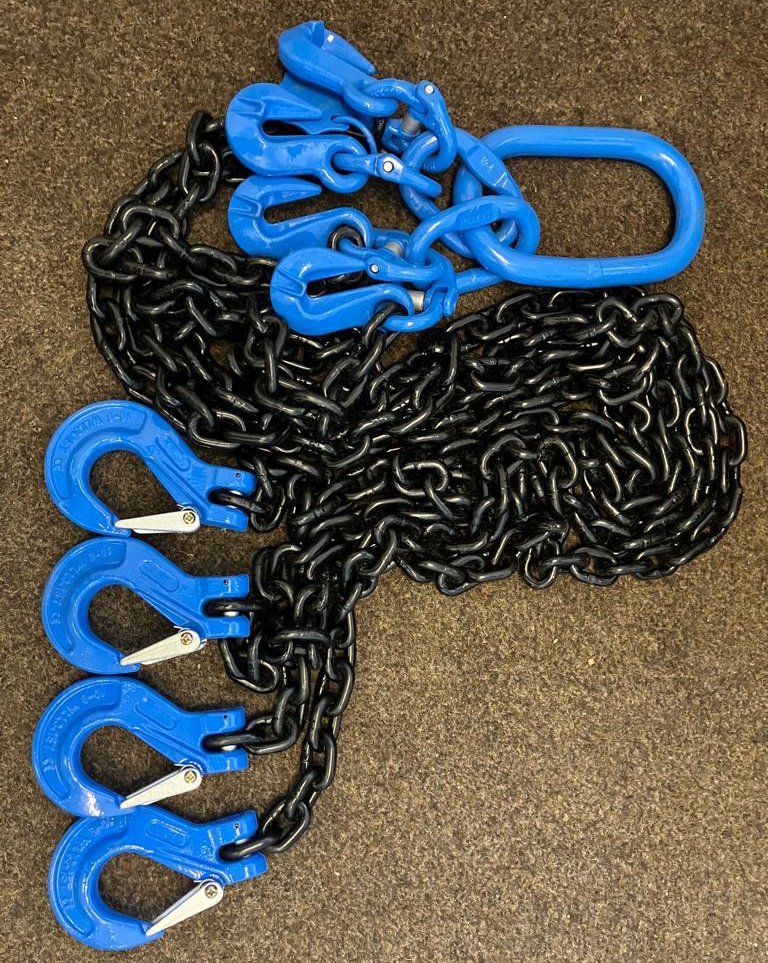

Chain slings

Chain slings are a type of lifting sling made from chains and used to lift and move heavy loads in industrial, construction, and manufacturing settings. They are designed to provide a strong and durable connection between the load being lifted and the lifting equipment, such as cranes or hoists.

Chain slings consist of a chain that is formed into a loop, with hooks or other attachment devices at the ends to connect to the load and lifting equipment. They may also include additional rigging components such as shackles, master links, or swivels to provide additional flexibility and versatility in lifting operations.

Chain slings are available in a variety of configurations to suit different lifting applications, such as single-leg slings, two-leg slings, three-leg slings, and four-leg slings. They may also be designed with different types of chain, such as alloy steel, carbon steel, or stainless steel, to provide different levels of strength and durability.

Like all lifting equipment, chain slings must be used properly and maintained regularly to ensure their safety and reliability. It is important to choose the right type of chain sling for the specific application, and to follow proper lifting procedures and safety guidelines at all times.

Round slings

Round slings are a type of lifting sling made from a continuous loop of synthetic fibers, such as nylon or polyester, and used to lift and move heavy loads in industrial, construction, and manufacturing settings. They are designed to provide a strong and flexible connection between the load being lifted and the lifting equipment, such as cranes or hoists.

Round slings are flexible, lightweight, and easy to handle, and can be used in a wide range of lifting applications. They are available in a variety of lengths, widths, and weight capacities to suit different lifting needs, and can be used in single-leg or multiple-leg configurations.

Round slings feature a protective outer layer that helps to prevent damage to the sling and the load being lifted. They may also include wear pads or sleeves to provide additional protection in high-wear areas.

Like all lifting equipment, round slings must be used properly and maintained regularly to ensure their safety and reliability. It is important to choose the right type of round sling for the specific application, and to follow proper lifting procedures and safety guidelines at all times.

Web slings

Web slings are a type of lifting sling made from a strip of synthetic webbing, typically nylon or polyester, and used to lift and move heavy loads in industrial, construction, and manufacturing settings. They are designed to provide a strong and flexible connection between the load being lifted and the lifting equipment, such as cranes or hoists.

Web slings are lightweight, flexible, and easy to handle, and can be used in a wide range of lifting applications. They are available in a variety of widths, lengths, and weight capacities to suit different lifting needs, and can be used in single-leg or multiple-leg configurations.

Web slings may feature loops or “eyes” at each end for attachment to the load and lifting equipment, and may also include wear pads or sleeves to provide additional protection in high-wear areas.

Like all lifting equipment, web slings must be used properly and maintained regularly to ensure their safety and reliability. It is important to choose the right type of web sling for the specific application, and to follow proper lifting procedures and safety guidelines at all times.

PICTURED: We used our webs sling during this installation at the Royal Academy of Arts.

Eye nuts

Eye nuts are a type of fastener that feature a loop or “eye” at the top for attachment to a lifting or rigging component, such as a hook, shackle, or chain. They are typically used to provide a secure and stable anchor point for lifting and rigging operations in industrial, construction, and manufacturing settings.

Eye nuts are available in a variety of sizes, materials, and weight capacities to suit different lifting needs, and may be made from materials such as steel, stainless steel, or brass. They may also feature additional features such as swivels or locking mechanisms to provide greater flexibility and security in lifting operations.

Like all lifting equipment, eye nuts must be used properly and maintained regularly to ensure their safety and reliability. It is important to choose the right type of eye nut for the specific application, and to follow proper lifting procedures and safety guidelines at all times.

Slings & lashings

Slings and lashings are types of equipment used in lifting and rigging operations to secure and move heavy loads in industrial, construction, and manufacturing settings.

Slings are flexible lifting devices made from materials such as synthetic fibers, wire rope, or chain, and are used to attach to the load being lifted and connect it to the lifting equipment, such as cranes or hoists. Slings may be configured in different ways depending on the load and the lifting application, and may include features such as hooks, shackles, or eye bolts for attachment.

Lashings, on the other hand, are typically used to secure the load being lifted to a surface or structure, such as a trailer bed or shipping container. Lashings may be made from materials such as webbing, rope, or chain, and may be configured in different ways depending on the load and the securing requirements. They may include features such as hooks, ratchets, or cam buckles for tensioning and secure attachment.

Both slings and lashings must be used properly and maintained regularly to ensure their safety and reliability. It is important to choose the right type of sling or lashing for the specific application, and to follow proper lifting procedures and safety guidelines at all times.

Contact Us

Address

Anchor House, Riverside Industrial Estate, Market Harborough, Leicestershire LE16 7PT, United Kingdom

Phone

01858 465599

Opening hours

Mon to Fri / 8am-5pm