Fabrication & lifting gear

Get in touch about Steel Fabrication & Lifting Gear

Steel fabrication & lifting gear

Lifting gear, which includes a wide range of equipment such as cranes, hoists, slings, shackles, and hooks, is designed to facilitate the lifting and movement of heavy objects in various industries, including construction, manufacturing, and shipping.

Some of the benefits of lifting gear include:

Increased efficiency

Lifting gear can help workers move heavy objects quickly and easily, saving time and increasing productivity.

Reduced risk of injury

By using lifting gear, workers can avoid the physical strain and potential injuries associated with lifting heavy objects manually.

Improved safety

Properly designed and maintained lifting gear can help prevent accidents and injuries in the workplace, ensuring a safer working environment.

Cost savings

Lifting gear can help reduce the need for manual labor and can increase the speed of tasks, resulting in cost savings for businesses.

Flexibility

Lifting gear can be used in a variety of settings, making it a versatile solution for moving heavy objects in different industries and environments.

Our expert engineers work closely with clients to understand their needs and develop custom solutions that meet their specific requirements. This can include custom designs, materials selection, and fabrication processes to ensure that the final product meets the necessary standards for strength, safety, and functionality.

Mobile gantries

Mobile gantries, also known as mobile gantry cranes, are a type of portable lifting equipment used for material handling and lifting operations. They consist of a horizontal beam or gantry supported by two or more vertical legs, which can be moved to different locations using wheels or castors.

Mobile gantries are commonly used in manufacturing, construction, and maintenance settings for lifting heavy items, such as machinery, equipment, and building materials. They are also used for loading and unloading trucks and other vehicles.

Mobile gantries come in various sizes and lifting capacities, and they can be electrically or manually operated. They are designed to provide a stable and secure lifting platform, and some models are equipped with adjustable heights and spans to accommodate different lifting requirements.

One advantage of mobile gantries is their flexibility and portability, allowing them to be moved easily to different locations within a facility or job site. They are also relatively easy to set up and operate, reducing the need for specialized training or equipment.

Jib Cranes

Jib cranes are a type of crane that consist of a horizontal member, known as a jib or boom, which is attached to a vertical mast or wall-mounted bracket. The jib rotates on the mast or bracket to provide a wide range of motion and lifting capabilities.

Jib cranes are commonly used in industrial and commercial settings for material handling tasks, such as loading and unloading trucks, moving heavy equipment or machinery, and transporting materials within a facility. They are also used in construction sites, shipyards, and other outdoor applications.

Jib cranes come in various types and configurations, including free-standing and wall-mounted models. They can also be powered by electricity, compressed air, or manually operated.

One advantage of jib cranes is their ability to provide localized lifting and movement of materials, reducing the need for workers to manually handle heavy items. They can also be customized to fit specific lifting requirements and are relatively easy to install and maintain.

Monorail runway systems

Monorail runway systems are a type of overhead crane system that consists of a single track or beam, known as a monorail, that supports a trolley or hoist.

The monorail is typically suspended from a building structure, allowing the trolley or hoist to move along the length of the beam to provide material handling and lifting capabilities.

Monorail runway systems are commonly used in manufacturing and production facilities, as well as warehouses and distribution centers, for moving and lifting heavy items, such as machinery, equipment, and palletized goods.

Monorail runway systems can be designed to accommodate various lifting capacities and span lengths, and they can be customized to fit specific facility layouts and lifting requirements. They can also be equipped with additional features, such as turntables, switches, and transfer carts, to provide greater flexibility and efficiency.

One advantage of monorail runway systems is their ability to provide a high level of precision and control during material handling and lifting operations. They are also typically more cost-effective and require less maintenance than other types of overhead crane systems.

Lifting beams

Lifting beams are a type of lifting equipment used for material handling and lifting operations. They consist of a horizontal beam that is supported by two or more vertical legs or hangers and designed to distribute the weight of the load evenly across the beam.

Lifting beams are commonly used in manufacturing, construction, and maintenance settings for lifting and moving heavy items, such as machinery, equipment, and building materials.

They are typically attached to a crane or hoist using shackles or hooks and can be customized to fit specific lifting requirements.

Lifting beams come in various sizes and lifting capacities, and they can be designed to accommodate different types of loads, such as unevenly balanced or fragile items. Some lifting beams are also equipped with adjustable hangers or lifting points to provide greater flexibility and precision during lifting operations.

One advantage of lifting beams is their ability to provide a stable and secure lifting platform, reducing the risk of damage or accidents during material handling operations.

They can also be relatively easy to install and operate, reducing the need for specialized training or equipment.

Spreader beams

Spreader beams are a type of lifting equipment used for material handling and lifting operations. They consist of a horizontal beam that is supported by two or more vertical legs or hangers and designed to distribute the weight of the load evenly across the beam.

Spreader beams are commonly used in manufacturing, construction, and maintenance settings for lifting and moving heavy items, such as large pipes, concrete slabs, or steel plates. They are typically attached to a crane or hoist using shackles or hooks and can be customized to fit specific lifting requirements.

Spreader beams come in various sizes and lifting capacities, and they can be designed to accommodate different types of loads, such as unevenly balanced or fragile items. Some spreader beams are also equipped with adjustable hangers or lifting points to provide greater flexibility and precision during lifting operations.

One advantage of spreader beams is their ability to provide a wider lifting base and balance the load, reducing the risk of damage or accidents during material handling operations. They can also be relatively easy to install and operate, reducing the need for specialized training or equipment.

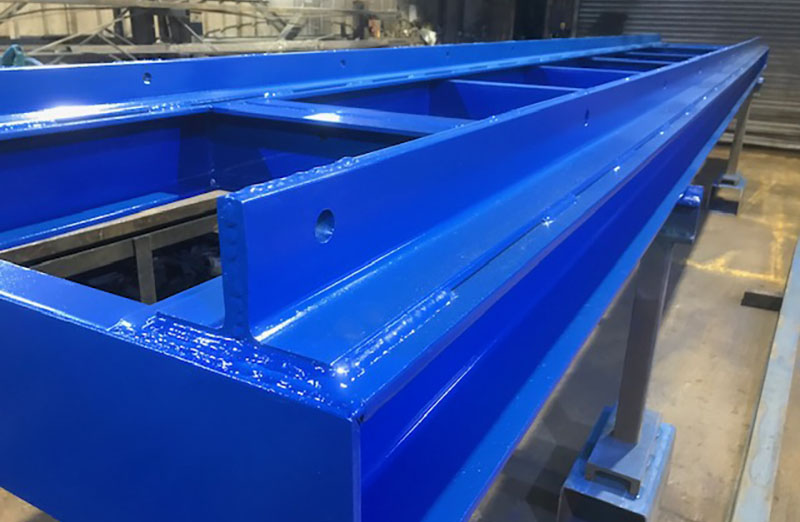

Fabrication & steelwork

Steel fabrication is the process of creating structures and components from steel materials through cutting, bending, and shaping.

We offer the production of standard and bespoke steel products and structures for various applications, including structural steel for building construction, custom metal fabrication for industrial equipment, and specialized steel products for specific applications.

The process of steel fabrication typically involves the use of advanced machinery such as cutting machines, CNC machines, and welding machines to create precise cuts, shapes, and connections between steel materials.

The end result is a high-quality steel product that is durable, strong, and able to withstand the rigours of various industrial and construction environments.

Our expert engineers work closely with clients to understand their needs and develop custom solutions that meet their specific requirements.

This can include custom designs, materials selection, and fabrication processes to ensure that the final product meets the necessary standards for strength, safety, and functionality.

PICTURED:

(Top) Modular Goods Lift fabricated for David Wilson Homes.

(Bottom) Bespoke heavy-duty racking fabricated for MOD Tank Spares.

Contact Us

Address

Anchor House, Riverside Industrial Estate, Market Harborough, Leicestershire LE16 7PT, United Kingdom

Phone

01858 465599

Opening hours

Mon to Fri / 8am-5pm